Types of Containers: Container Selection Made Easy

Choosing the right type of container for your shipping needs can be daunting.

Many types of containers are available, ranging from dry containers to insulated containers to refrigerated units. It’s important to understand the types of containers and their uses to make an informed decision on which one is best for you.

So what are the different types of containers and how do you determine which option is best for your shipment.

What are the three most common types of containers

Your most pressing worry when shipping cargo is most likely ‘Will my wine arrive in good condition?’

This is especially a concern for anyone moving vulnerable or perishable products, including pharmaceuticals, certain chemicals, and, of course, consumables such as wine. Imagine the amount of wasted resources if products end up unfit for use or consumption right and the cost of unsellable items!

The biggest culprit in spoiling wine during transit is thermal shock, but contamination and humidity can also wreak havoc. Extreme shifts in temperature and humidity can cause irreparable damage to consumables if not managed properly.

If not transported correctly, food or beverage items may not taste as they should. So choosing the right container for your cargo becomes a make-or-break decision.

So, which container to choose?

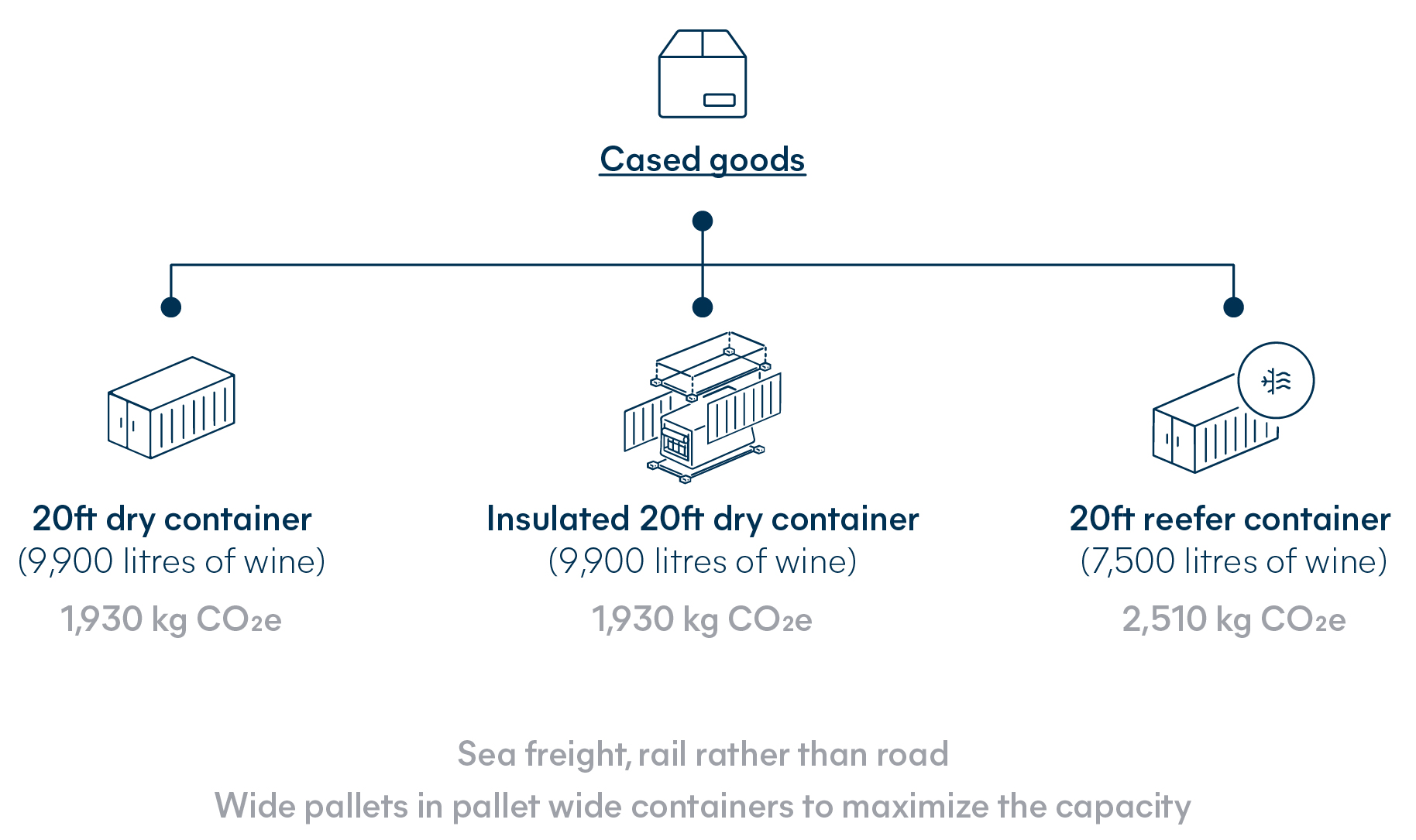

The three most common types of containers are:

Let’s break down these three container choices and in which situations each container type is appropriate.

Types of containers: Making the right choice

![]()

Dry containers

For items not negatively impacted by things like temperature, humidity, or bad smells, your standard dry container is the budget-friendly, no-frills choice.

They are usually readily available anywhere in the world, however, the current freight chaos and container imbalance has made availability unpredictable these days.

Dry containers for sea shipping typically come in two sizes, twenty foot and forty foot.

These are suitable for packaged products and if you are bulk shipping liquids, a flexitank can be placed inside them too.

![]()

Insulated containers

For cargo that does need safeguarding from thermal shocks, humidity infiltration, condensation, cross-contamination, and odors, upgrading to a container to include a specialized insulated liner is a wise move.

Insulated liners don’t refrigerate or heat your products, but they are a state of the art solution that prevent those damaging spikes or dips in temperature that can spoil wine and other consumables. Plus, they offer protection from contamination as they fully seal a container in a food-grade quality lining, without compromising on space or eco-friendliness.

A big step up from a basic dry container!

Insulated liners from Hillebrand Gori are excellent at reflecting heat. Our own cutting-edge and patented VinLiners boast a 94% heat reflection, almost double the reflection that competitor liners offer.

Once cargo is loaded and sealed inside the liner, the internal temperature will only ever increase to a maximum of 11ºC/20ºF (from packing temperature). This dry container add-on protects your products efficiently for even the longest transits of 40 days or more.

Apart from being a much more cost-effective choice for temperature control, upgrading a dry container to include a liner is an environmentally friendly option as well. Hillebrand Gori insulation liners offer a 23% reduction in greenhouse gas emissions compared to reefer containers, and are recyclable.

![]()

Refrigerated containers (AKA Reefers)

When nothing less than exact temperature setting is required, be it hot or cold, reach for the refrigeration unit! For perishable and sensitive products that need to-the-degree cool temperatures, refrigerated containers are the solution.

Similarly, products that need to be kept at steady warmer temperatures such as aqueous polymers, can also be transported in a reefer that is set to perform as a heater.

Reefer container refrigeration units circulate cool air like a giant fridge, and this is usually controlled digitally.

However, they are a more costly choice and not the most environmentally friendly of containers. A refrigerated container with its refrigeration unit disabled is known as a Non-Operating Reefer.

Its insulating walls stabilise internal temperatures to a degree, but there is less storage space and a higher price compared to a dry or insulated container.

Summing it up

Depending on the sensitivity or your products and what the climatic conditions likely to be faced on a voyage, will determine which types of containers and level of protection is required.

Don’t worry, our experts will help you make the right decision. When you choose to move your products with us, we analyse your planned route in detail and prepare for what’s to come with highly accurate climate predictions from the WMO (World Meteorological Organization).

You can rest assured that we’ll help you to pick the right container type for your cargo, every time.