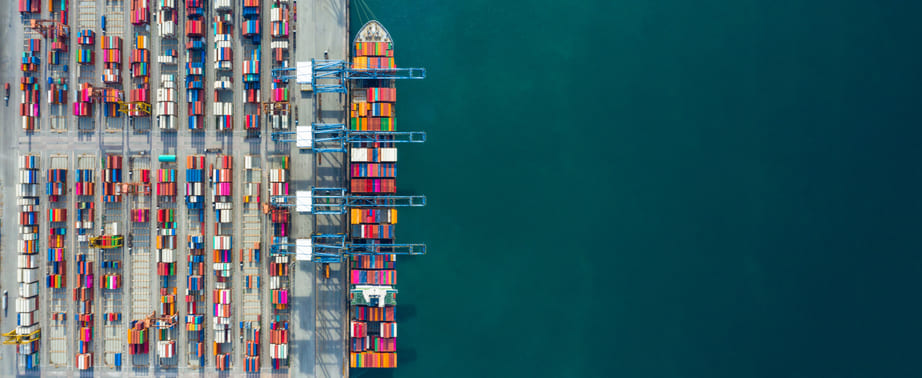

The global container shortage: How it's affecting the supply chain

The global container shortage continues to wreak havoc on the global supply chain, causing a ripple effect on businesses worldwide as they struggle to get their products to market.

Considering the significant impact the container shortage has had on the global economy, it’s worth exploring what led to the crisis and what it means for suppliers and consumers?

What is the state of the container shortage, and how did we get here?

The global container shortage was caused by a perfect storm of events, including the COVID-19 pandemic, which has led to a decrease in the availability of containers.

In early 2020, a series of lockdowns — that began in China and then quickly spread through Europe, the United States and worldwide — led to the halt of economic movement and production. This created the North American supply chain bottleneck.

The container shortage can be attributed to the following factors, including:

- The reduced number of available containers and operational vessels

- Congested ports because of a COVID-related labor shortage that still exists and is expected to carry into 2023

- A change in consumer’s buying behavior caused irregularities in purchases and demand, greatly affecting the flow of shipping containers

What does the global container shortage mean for suppliers and consumers?

Suppliers and consumers around the world are feeling the effects of container shortages.

The ability to meet demand is an essential part of being a supplier. When this is not possible, it can have a massive impact on businesses and, by extension, consumers.

For suppliers, the container shortage has led to:

- The slowing of international trade for goods

- Erratic production due to unpredictable delivery of raw materials

- A loss of earnings

- Difficulty in meeting consumer demand (which is a threat to brand reliability and positioning)

For consumers, the container shortage has resulted in:

- Reduced or empty shelves

- Having to decide whether to stick with their brand of choice or try another option due to the unavailability of certain products

- Increased prices for goods

With that said, the current situation shows no signs of abating anytime soon, so it’s vital for suppliers and consumers alike to be aware of how the container shortage might affect them now and into the future.

Vessel capacity and meeting global demand amid a container shortage

When manufacturers shut down factories in response to the pandemic, this caused large numbers of containers to be stopped at ports.

In response, carriers reduced the number of vessels out at sea to stabilise costs and the erosion of ocean rates. This meant empty containers weren’t picked up, significantly impacting Asian traders who couldn’t retrieve empty containers from North America.

According to a recent report by Windward, 1-in-5 (20%) of container vessels globally were waiting outside a congested port. And nearly 25% of those unberthed ships were still waiting outside of ports in China.

What does the future hold?

Drewry supply chain advisors predict that the latest global container disruption will worsen for importers before experiencing a partial improvement.

While there has been a reduction in Shanghai port calls since mid-April, sea-side congestion has worsened (peaking at 277 vessels). It’s estimated that up to 260,000 TEU of export cargo (an equivalent of 26 fully-loaded 10,000 TEU container ships) wasn’t shipped because of the Shanghai lockdown.

How to navigate the container shortage

There are some things suppliers you can do to navigate the container shortage:

- Increase inventories, anticipate and allow for longer lead times.

- Adapt to reduced container free times, expect higher per diems linked to delays and landside bottlenecks.

- Prioritise long-term contracts and secure capacity.

- Consider air freight alternatives for urgent flows.

Hillebrand is here to help you navigate the container shortage and keep your business running smoothly. Contact us today to learn more about how we can help or request a quote.

.png?sfvrsn=cb1fc0fd_1)